cutter grinding techology

Cutter grinding is a technology requires very high repair worn when can greatly improve efficiency and save tool use costs, the Division I professional production and sales of universal tool grinder, tool grinder enterprise, the following brief introduction to some of the cutting tool grinding the basis of knowledge.

First, the tool material

Cutter grinding tool materials: high-speed steel (HSS), powder metallurgy high speed steel (PM-HSS), carbide (HM), and PCD, CBN, cermet superhard materials. High-speed steel cutting tools sharp, good toughness, high hardness, carbide cutting tools but poor toughness. Carbide cutting tools density was significantly greater than the high-speed steel cutting tools. These two kinds of materials is the main material of the drills, reamers, milling cutters and taps. The performance of powder metallurgy high speed steel ranged between these two materials, mainly used in the manufacture of coarse cutter and tap.

High-speed steel cutting tools, good toughness, it is less sensitive to the collision. Carbide cutting tools of high hardness and brittle, is very sensitive to the collision, the edge is easy to jump. Therefore, in the process of grinding of carbide cutting tools to operate and be placed very carefully to prevent the fall of the collision between the tool or tool.

Since the accuracy of the high-speed steel cutting tools are mostly relatively low, its grinding requirements, coupled with its price is not high, so, many factories set their own tool workshop for grinding it. Carbide cutting tools are often sent to the center of the specialized grinding grinding. According to the statistics of the the Arnold tool grinding centers, more than 80% of the repair tool is a carbide cutting tools.

Second, the tool grinder

The tool material is very hard, so generally only uses grinding to change its shape. In the manufacture of cutting tools, grinding a common tool grinder are the following:

1 mill slot machines: grinding drill bits, end mills, tool shafts or the back.

Two grinding angle: the cone angle of the drill grinding (or eccentric angle).

3 repair cross edge: Amendments to the drill chisel edge.

(4) manual universal tool grinding machines: cylindrical grinding, groove, back angle, chisel edge, plane, rake face. Commonly used in a small number of complex shape tool.

5.CNC grinder: the general five-axis, the function determined by the software. Generally used for grinding large quantities, high precision, but a complex tool, such as drills, end mills, reamers. The main supplier of such grinding machines from Germany, Switzerland, the United States, Australia and Japan.

(3), the wheel

1. Abrasive

Different material from the grinding wheel abrasive tool suitable for grinding of different materials. Different parts of the tool requires the use of abrasive size to ensure that the best combination of edge protection and processing efficiency.

Alumina: used for grinding HSS tool. Wheel is inexpensive, easy to fix into a different shape for grinding complex tool (corundum classes).

Silicon Carbide: used to correct the CBN grinding wheel and diamond wheel.

CBN (cubic boron nitride): used for grinding HSS tool. Prices, but durable.

Internationally, the wheel with a B to represent, such as B107, 107 the size of the abrasive diameter.

Diamond: HM tool used for grinding, high prices, but durable. Wheel, such as D64, 64, said the size of the abrasive diameter D to

2 Shape

For convenience in different parts of the grinding tool grinding wheel should be a different shape. The most commonly used are:

Parallel to the grinding wheel (1A1): grinding angle, diameter, back, and so on.

Disc wheel (12V9, 11V9): grinding spiral groove, the master of the cutter, Vice cutting edge repair cross blade and so on.

Need to fix its shape (including flat, angle, and rounded corners R), the wheel after a period of use. The wheel must always clean up stone to fill in the abrasive between the chips cleared away in order to increase the grinding capacity of the grinding wheel.

Fourth, grinding the standard

Do you have a good set of tool grinding the standard is whether the measure of a grinding center professional standards. Grinding standard, the general provisions of the different tools in the cutting of different materials, the cutting edge of technology parameters, including the blade angle, angle, rake angle, angle, inverted blade, chamfering parameters (in the carbide drill blade passivation process is called "inverted edge" down the width of the blade with the cutting material, generally in the 0.03-0.25

Mm. Process called "chamfer chamfer edge on (tip points). Every professional company has years of summary from the grinding standards.

HM drill bits, HSS drill bit of difference:

HSS drill: angle of 118 degrees, sometimes more than 130 degrees; sharp blade; relatively low accuracy (blade height difference, symmetry, weeks to beat) requirements. Chisel edge, there are a variety of amending the law.

HM drill: general angle 140 degrees; straight flute drill is often 130 degrees, three blade drill 150 degrees. Blade tip (edge on) is not sharp, often passivation, or down the edge and chamfer; high precision. The chisel edge is often cultivated itself into the S-shaped, in order to facilitate chip breaking.

Horn:

Blade of the posterior horn of the tool, is very important. Posterior horn too much, edge virtual easy to jump, "bar knife; the posterior horn is too small, too much friction, unfavorable cutting.

With the posterior horn of the tool cutting materials and tool types, tool diameter different different. In general, the larger angle with the tool diameter decreases. In addition, the cutting material, hard, posterior horn, otherwise, the posterior horn bigger.

5, tool testing equipment

Tool testing equipment is generally divided into three categories: the knife, projectors and universal tool measuring instrument. Mainly used for machining centers and CNC equipment on the knife knife in preparation (eg, length, etc.), can also be used to detect the angle, radius, step length and other parameters; projector function is also used to detect angle, radius, step length and other parameters . However, the above two general can not measure the posterior horn of the tool. Universal tool measuring instrument can measure the vast majority of geometric parameters of the tool, including the posterior horn.

Therefore, the tool professional grinding center must be equipped with a universal tool measuring instrument. Supplier of such equipment on the market the products of Germany and France.

Repair mill mechanic

The best equipment requires personnel to operate the grinding mechanic training is naturally one of the most critical part. Severe shortage of tool manufacturing in China is relatively backward, and vocational and technical training, tool grinding mechanic training only by the enterprises themselves.

Due to the particularity of tool grinding industry, Arnold draw German mechanic training methods and work out a cutter grinding mechanic technical level of evaluation criteria based on their years of experience. Grinding mechanic of the class is divided into eight, eight is the highest. A technical school graduates in the Arnold company after six months of training and practice generally can achieve the level of three craftsmen.

VII Conclusion

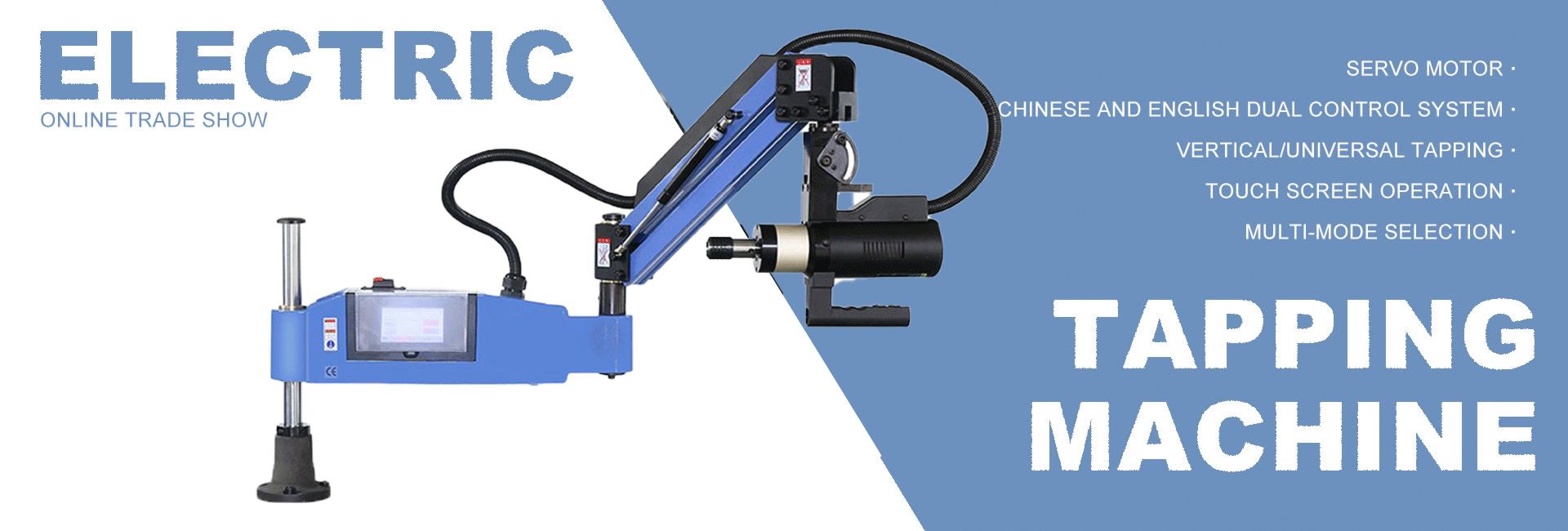

Dongguan Rio Seoul mechanical professional production and sales of universal tool grinder, electric tapping machine, drill grinders, cutter grinders, wire tapping, grinding machine universal grinding machine, tool grinder, with the grinding equipment, testing equipment and other hardware and repair grinding standard grinding technicians and other software, precision tool grinding work can begin. Due to the complexity of the application of the tool, professional grinding center must be repaired according to the grinding tool failure modes of renovation grinding program and track the effect of tool use. A professional tool grinding center must also be constantly sum up experience, tool repair worn better, more specifically

Latest News

Contact Us

Name: Nina

Tel: 0086-0769-81177281

Fax: 0086-0769-81177281

Mobile: 0086-13712515491

E-mail: [email protected]

Skype: toolsharpener

QQ: 19641516791

WeChat: 0086 13712515491

Whatsapp: 0086 17727718926

Add: No 1 industrial avenue, Hengli Town,Dongguan city,Guangdong provience,China

CHINESE

CHINESE ENGLISH

ENGLISH

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online