Drill grinder operation manual

Standard Operational Steps:

1. Determine the drill material to choose grinding wheel:

HSS material drill use CBN grinding wheel

Carbide / Tungsten material use SDC grinding wheel

2. Choosing the Proper Collet:

According to the drill diameter and choose the same size of collet. Eg: 5mm drill, use 5mm collet ; 5.5mm drills, use 6mm collet.

3. Make sure there are no dust or scraps inside the collet and the collet holder.

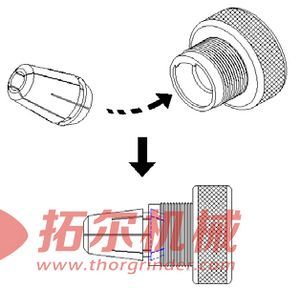

Insert the collet into collet holder by 45 ゚degree:(Diagram 4-1)

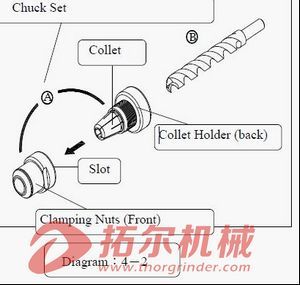

5. Assembling Steps:

【(B)Drill;(A)Insert collet into collet holder and assemble them with the clamping nut】。(Diagram 4-2)

※ Fasten the chuck set until the drill is grabbed by the holder, do not fasten Chuck Set too tightly, please leave some space for the later adjustment.

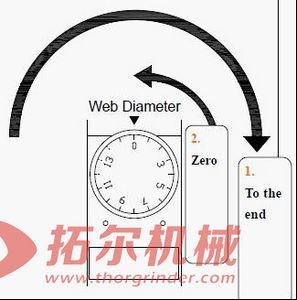

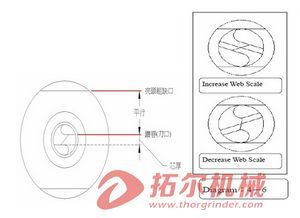

6. Web Diameter Scale Adjustment:

Set at Zero:1. Turn the Web Diameter to the end by clockwise. 2. Then set the Web Diameter to “zero”.

Adjustment: Adjust the Web Diameter scale according to the drill diameter.

Eg : 10mm drill, set at 10

Eg : 10.6mm drill, set at 11

Eg : 10.2mm drill, set at 11

【If the length of a drill is shorter than original length after re-sharpening many times, the web scale should be increased until the cutting edge is parallel with slot of clamping nut.】

※ For grinding High Spiral Drill Bit, please increase the web scale more than its original diameter

Diagram:4-3

※ For grinding, Deep Hole Drills increase the adjustments on the Web Diameter scale (Diameter x 2).

Eg: Deep Hole Drill, diameter at 10mm, the Web Diameter scale should adjust above 20.

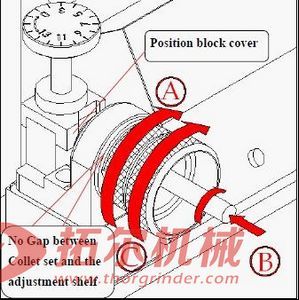

Drill Positioning:

A. Inserting the chuck set fitly into the adjustment shelf and turn it clockwise to the end.

B. Push the drill to the end and turn slowly the drill by clockwise until it is blocked by the position block.

C. Tighten the clamping nut and the chuck by clockwise

D. Take the chuck set out by turn it counter

clockwise

Always keep the parallelism before starting the grinding procedure.

Note :When taking the chuck set out, please make sure the cutting edge of the drill is parallel with the slot of clamping nut, if it is arallel, please re-adjust it.

You could also choose to use the parallel alignment device to check the parallelism. ( See page 29. for the use of Parallel Devise)

Grinding Cutting edge:(Point Angle)

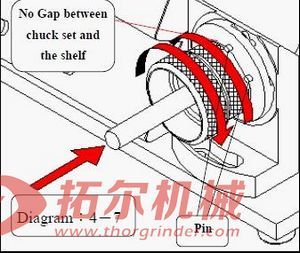

Turn on the switch, when the motor rotation is stable (about 10 seconds), put the chuck set into the grinding shelf (on the bottom of right hand side) – Make Sure connect closely

The slot of the fixed clamping nut must be fitted with the two pins on the grinding shelf.

Grind the drill by moving left and right until the noise stops.

Turn to the other side and grind the drill by the same way. (Diagram 4-7)

Point Angle is available for adjustment.(90°~145°)

While grinding, please do not hold the drill shank , it may influence the drill position and caused the missing of accuracy.

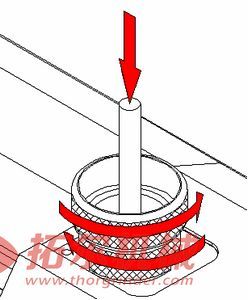

Web / Center Thinning:

Insert gently the chuck set into web thinning shelf until reach the grinding slip, then grind the drill by moving left and right until the noise stops. Take out the chuck set, turn the chuck set to the other side and grind by the same way.

Please make sure the center part of clamping nut slot aligns to the pin, when putting in or taking out the chuck set.

There are 0.1mm shim and 0.3mm shim for adjusting the size of web thickness.

V. Replacement of Grinding Wheel and Machine Maintenance:

Replacement of Grinding Wheel:

Please unplug the power supply line before conducting replacement action.

Loosing the screw on the grinding wheel cover, then using hexagon wrench to loose the screw on the fan by counter clockwise and take the fan and grinding wheel out.

Use wiper to clean the scraps on flange and washer before replacing new grinding wheel.

Assembling the grinding wheel, fan, washer with screw.

When fastening the screw, do not over push; tighten it until the fan can’t be moved only.

Latest News

Contact Us

Name: Nina

Tel: 0086-0769-81177281

Fax: 0086-0769-81177281

Mobile: 0086-13712515491

E-mail: [email protected]

Skype: toolsharpener

QQ: 19641516791

WeChat: 0086 13712515491

Whatsapp: 0086 17727718926

Add: No 1 industrial avenue, Hengli Town,Dongguan city,Guangdong provience,China

CHINESE

CHINESE ENGLISH

ENGLISH

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online